Many young Nigerians are making waves in the area of entrepreneurship. They have shown that Nigerians can be counted among the comity of nations in the areas of creativity, innovation and technology. One of such young people is Jerry Isaac Mallo.

Jerry Isaac Mallo was born on July 20, 1994 in Jos, Plateau State of Nigeria. He studied Mechanical Engineering at University of Hertfordshire in the United Kingdom. Since graduation, he has been laying solid foundation for the growth of the manufacturing sector in Nigeria. He set up Bennie Technologies, where he is the Chief Executive Officer, with a vision to revolutionize creativity and innovation in the country. As a fabrication engineer, the young Jerry has manufactured Bennie Purrie, (carbon fibre sports car), agricultural machines, and ventilators.

The Qoheleth in this report gathered that these massive achievements have attracted international attention and solidified his position as a trailblazer in engineering and technology within Nigeria and beyond. With each stride, he lays a future foundation for entrepreneurship development by challenging conventional wisdom and embracing untapped potential in the country.

Jerry in the beginning went in for arts but later changed to science when he entered the senior secondary school. Just like many other innovators, his creativity came through inspiration.

On the invention on agriculture, he said; “My inspiration came from the hardship I passed through. My parents are farmers and are always on the farm and we did things the hard way. I just felt there should be a way to make things easier and faster. I did it out of passion and it gave me joy. I officially made it a business when I learnt that there was high demand for agricultural equipment. When I came back from London, I realized that money could be made from it. So basically, I did it to raise funds to do what I was passionate for; which is making cars. However, that is not an immediate need in Nigeria right now, so we decided to pick the immediate need, which was agricultural equipment. I delved into the agricultural sector, while not forgetting my passion for fast cars.”

He sees his company, Bennie Agro growing as one of the top (companies) in the manufacturing world and one of the giants of manufacturing in Africa.

Jerry’s passion is to build cars. He started building fast cars when he was five years old. According to him, he produced the first car when he was in SS3. It was a skeletal job and it didn’t look too good but it moved. It was made with the engine of a grinding machine. It was kick-started from behind like a generator, while I sat inside and controlled the vehicle. It took four months to build, from designing sketches to the completion of the car.

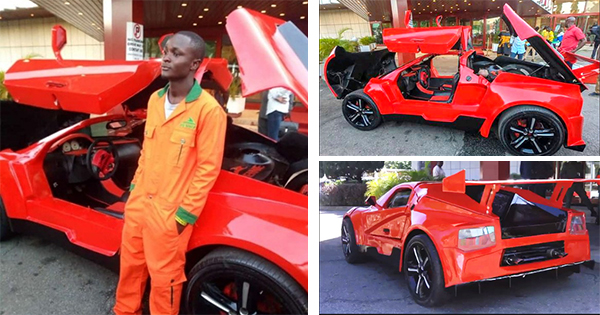

But the one that launched him to limelight is Bennie Purrie, a carbon fibre sports car. It is actually not a carbon fibre vehicle; it is a fibre glass vehicle. Fibre glass is basically fibre got from glass. It has almost all the characteristics of glass.

It has the ability to absorb shock and when it gets pushed to the limit where it can no longer absorb (shock), it shatters. The aim is to see that vehicles don’t squeeze people, so that they would be able to come out safely (in case of accidents). He did this when he was 25 years. In a bid to save more people from auto crashes, Mallo explained that most people get crushed and mashed in cars because those cars are made from aluminium or galvanized sheets that cannot absorb shocks at high speed.

He said that his cars are made of fibres which have the characteristics of glass, noting that if they get hit, they break like bottles and the airbags protect the individuals.

Mallo said the cars are also made with tubular chassis in that it gives a firm body to the car which makes it rugged for Nigerian roads.

In a bid to ensure the cars are conducive temperature-wise, Mallo stated that the vehicles have great cooling systems, with four radiators to ensure that the cars are cool regardless of the temperature.

Regarding the speed, the fabricator says his first model goes from 0 to 120 in 12seconds. He adds that it is a 2.0 litre engine car which produces about 130 big horsepower.

He promised to produce more vehicles on monthly basis if there is availability of funds.

Speaking about his motivation especially at such a tender age, he said; “As far as I’m concerned, we haven’t done anything great. I don’t know why people feel 25 is a young age. I actually feel old at that age. I am self-trained. I tutored myself on the Internet, learning from people that are ahead of me. A lot of people feel that it has a lot to do with the university I attended but I don’t think so, because virtually everything (I know) is self-taught.” He got a lot of information from the social media especially pages that teach about how cars were manufactured which he shared with his colleagues.

Despite the challenges in the country especially in the area of finance, the young engineer forged ahead. He had twice shut down his company but later started all over again. “In Europe, we learnt that making the car is just half of the challenge, and selling it is the other half; Africa is usually is the target place to sell these vehicles, so I feel there’s a big market for it here,” Mallo stated.

Jerry was encouraged to carry out his vision when he noted that almost all the materials and resources required to manufacture his products can be sourced from Nigeria. And wondered why vehicles are not produced in the country

Speaking further on the reason he delved into creating such a luxurious vehicle, Mallo said there are a lot of hand-skilled individuals in Nigeria who are wasting away because the nation tends to favour the theoretical more than the practical.

He said he was challenged and had to do something “practically inclined” which would serve as a platform for other skilled persons to put their hands together and come up with beautiful products.

The Qoheleth had earlier reported that Jerry Mallo ventured into the health sector during the Covid-19. He produced ventilators to assist Africans who could not afford the medical equipment at that time as well as those who had the funds but could not lay their hands on the equipment.

Jerry Mallo did not put all his eggs in one basket. He built a team around him and encouraged other young Nigerians to key into his vision. He did this by organizing workshops and free skills and vocational training in the areas of fabrication, design, basis of manufacturing, communication skills and financial literacy. During such exercise, the passionate ones were picked and employed. According to him, there are Masters degree holders who apply for the jobs. These people are tested to know their level of performance.

Despite his tight schedule, Jerry also creates time for leisure. He likes to ride power bikes. He also makes out time for his community where he mentors children to follow his footsteps thus, he is called “baba yaara” which means “father of children. His dedication to his family, community, and craft is a testament to his character and commitment to positively impacting the world.

Jerry Mallo’s net worth is estimated at over $1million. His achievements have attracted many accolades worldwide among which are Future Awards Prize for entrepreneurship and Forbes Africa’s under 30.